About Vessels

Dissolution vessels

Specification

USP: For a 1 litre Vessel

Height: 160-210mm.

Outside Diameter: 98-106mm

Hemispherical Bottom

Discussion

Dissolution Vessels are a critical part of the apparatus and should be treated as a precision part, just the same as other parts of the tester. It can be argued that they are one of the most critical parts of the whole dissolution test and studies demonstrate just how much influence vessels have on the final results.

|

|

|

|

|

|

|

|

1000ml Clear |

1000ml Amber Glass Vessel |

Precision |

Plastic Vessel |

500ml Vessel |

200ml Vessel |

100ml Vessel |

Glass Vessels

Dissolution vessels play a big part in the dissolution process and it is perhaps surprising that such a large tolerance in the inside diameter is allowed.

Part of the justification for this is that most vessels are formed from extruded glass tubing and this has significant variations in its ID. Also the hemisphere at the bottom of the vessel has traditionally been hand formed and this makes it hard to manufacture to a tight tolerance.

Additionally the flange at the top can affect the centering and the vessel verticality. Recently some bath manufacturers have started to make the flange out of moulded plastic which is both more reproducible and allows the vessels to be rigidly fixed into the tester and prevents rim chipping and breakage.

Unfortunately all the major bath manufacturers specify different diameter glass, meaning there is no “one size fits all” vessel. Mixing vessels may cause problems with height, centering and flow dynamics thus generating inconsistent results. This should therefore be avoided. Third party vessels our vessels should be guaranteed to meet the specification of the original vessels.

Amber vessels are used to reduce the amount of light that can get into the vessel for light sensitive applications and should be used with amber vessel covers. They normally allow enough light in for the dissolution process to be visible. PTFE vessels that are totally opaque and do not allow any light to pass through are also available.

All vessels should be serialised and where possible used in the same bath location and orientation to minimise the physical differences.

Plastic vessels.

There is sometimes a temptation to use plastic vessels to save money, but in reality this is usually a false economy. Plastic vessels are easily scratched, crack very quickly and have much poorer heat transmission than glass vessels

Plastic vessels (or PTFE coated glass vessels) are sometimes used where the dosage form will stick to a glass vessel. All plastic vessels are moulded and should be reproducible. However they are generally easy to scratch and care should be taken when cleaning them.

because of the poor thermal qualities, to ensure the temperature inside the vessel remains at 37C the temperature of the waterbath has to be set higher than normal.

Vessel Shape.

There have been various studies into the effect that the shape of the vessel. Two of the best publications are detailed below. The first publication discusses the large physical difference between the vessels available. The second article demonstrates that the fewer defects the vessels have, the more reproducible the results will be.

http://www.dissolutiontech.com/DTresour/200702Articles/DT200702_A04.pdf

http://www.dissolutiontech.com/DTresour/200511Articles/DT200511_A02.pdf

Precision vessels.

More recently QLA pioneered a new method of making vessels using a mould that ensures they are all identical. Much like injection moulding of plastic, injection moulding of glass significantly reduces the variation in the vessel diameter, sphericality and height to within +/- 0.2mm. These vessels have ground glass rims can be freely moved within a bath (or replaced if broken) without having to recalibrate.

More importantly, because the vessels are essentially identical, the variation in results from position to position is significantly reduced thus reducing CV readings and making it easier to reach the tighter PVT variation specifications.

The vessel can be used in most dissolution baths with the use of an simple adapter ring. They should be used as a complete set – it is not recommended to mix precision vessels with traditionally manufactured vessels.

Peak Vessels

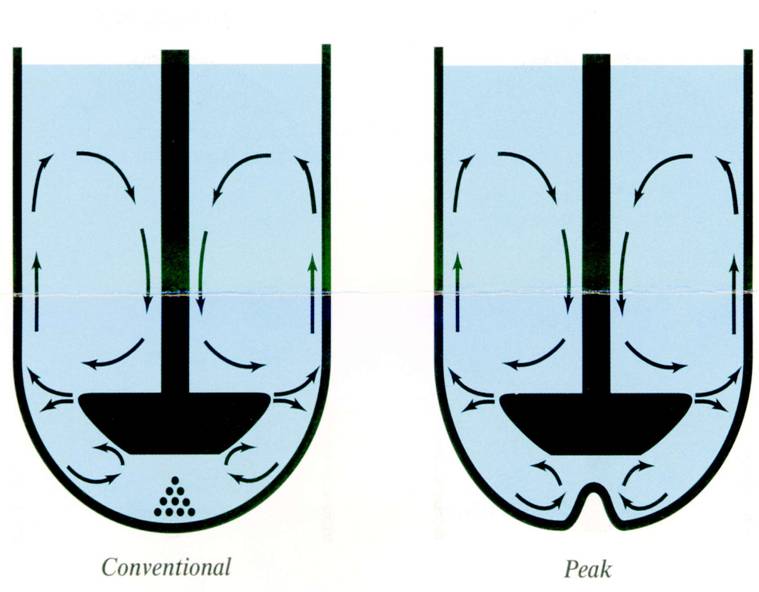

Peak vessels have a small peak at the bottom of the vessel. This peak is designed to prevent cone formation during the test. The use of these has split opinion. Whilst some people say that they make the dissolution process more repeatable with improved hydrodynamics, others say that it removes the discrimination of the test and similar results can be obtained by simply stirring the vessel at a faster speed. Also the height and shape of the peak is hard to define and not easy to reproduce.

If peak vessels are used their use has to be justified and an explanation given why a standard vessel is not suitable. Some products that have methods based on these vessels have however made it into production

An article discussing Peak vessels can be seen here

http://www.dissolutiontech.com/DTresour/1996Articles/DT199605_A02.pdf

Cleaning Vessels

Sticky residues can easily build up on the surface of a glass vessel and it is essential that they are cleaned properly

One method is to wash the vessels thoroughly in soapy water, followed by multiple rinses in DI water and a rinse in Ethanol before drying.

The use of an automated washer is also possible but checks should be made to ensure that no residues are left.

After cleaning, and before the next use, vessels should be checked for scratches and chips that could occur during the cleaning process. Simply holding a vessel up to the light is a good way to spot irregularities.

Vessel Sizes

Although the standard vessel size is 1 litre, there are many other sizes available from 4 litres down to 100ml. In all cases reproducibility is essential and all vessels have a hemispherical bottom.

| Size of Vessel | Typical Use |

| 4 Litre | Sample Pooling, Veterniary Applications |

| 2 Litre | Low Solubility Drugs |

| 1 Litre | 100ml, 900ml and 500ml Tests |

| 500ml | 500 ml Tests |

| 350ml | Low Dosage Forms Requires special paddles |

| 200ml | |

| 100ml |